Are you looking for a durable, beautiful and economic way to cover and/or protect your product? Our caps, protective sleeves or special products offer a great solution.

Request QuotationLoVen Special Products

As standard, we use phthalate-free black, yellow, red and fluorescent green material. All ingredients are individually FDA approved.

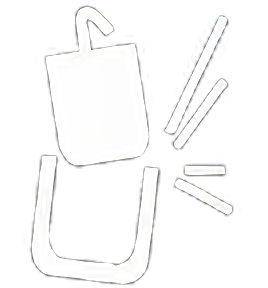

First we make a mould. The mould determines the internal shape of the product.

The mould is preheated in an oven.

The mould is attached to a special frame and then dipped in a bath of liquid vinyl/plastisol.

The frame is automatically transported to an oven in which the product cures completely.

The mould is dipped in water to cool it.

Compressed air is used to eject the final product from the mould.