As standard, we use phthalate-free black, yellow, red and fluorescent green material. All ingredients are individually FDA approved.

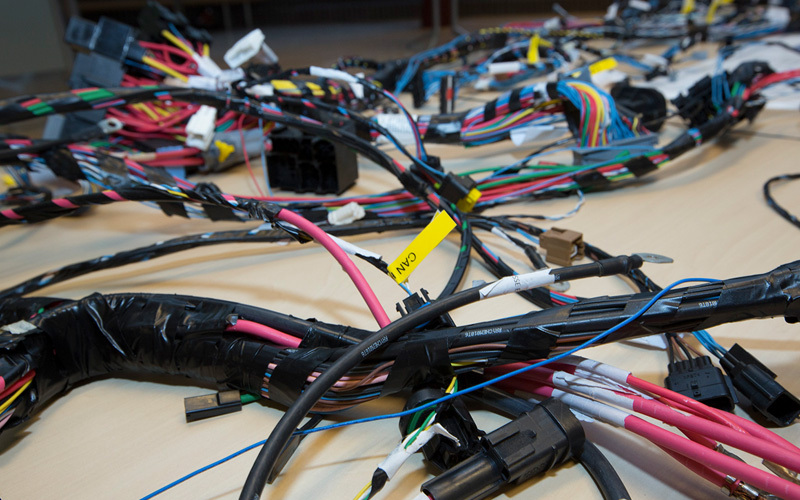

The dip molding process is ideal to consistently create seamless, flexible vinyl plastic parts of high quality. The process is fast and relatively inexpensive compared to other molding techniques such as injection molding. In the automotive industry, car manufactures use many plastic parts like clips, caps, sleeves, covers, and panels while assembling cars. Using the dip molding process, these parts can be produced without seams and in the exact color that is needed.

If you count all the parts that are in a car, from the wheels to the smallest screws, then an average car holds more than 10,000 parts. A lot of these parts are plastic covers, caps, sleeves and tubes. The dip molding process is suitable to create these products to the exact specifications that are required.

The biggest advantages of dip molded vinyl parts are the flexibility of the product and the possibility to create a product without seams. For example, dip molded vinyl caps won’t tear under stress and are easily fitted.

Other advantages:

When it comes to dip molded automotive parts, LoVen special products is your professional partner. We can provide you with standard caps in different sizes and colors, but can also create custom products to your exact specifications. Feel free to contact us with regards to your specific needs.